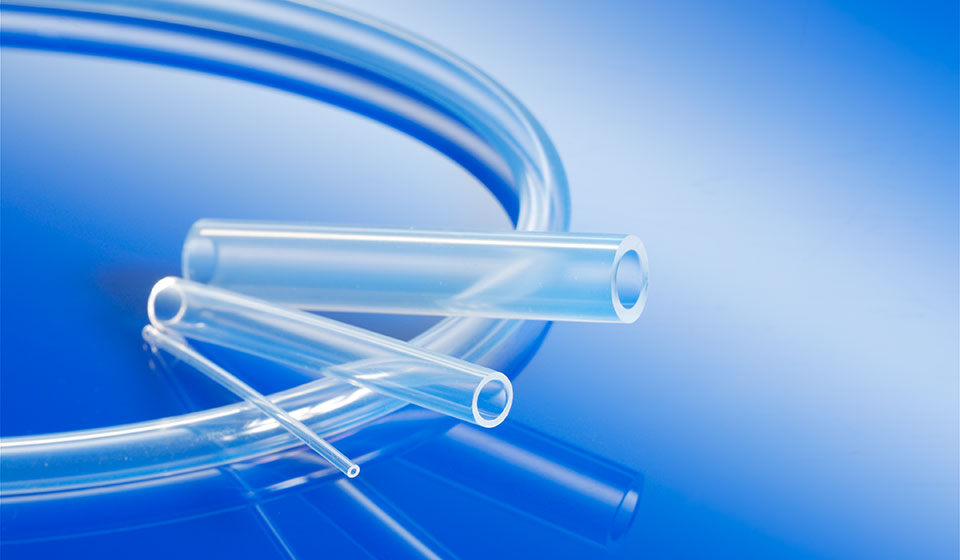

PFA-FLEX-TUBES: The new generation of PFA high performance tubes

Raw material information

PFA-Flex is a modified version of standard PFA and outperforms regular PFA grades by a higher mechanical strength when being under a permanent dynamical and mechanical stress.

The bending fatigue strength is excellent and among the highest of all fluoroplastic materials according to MIT-values.

These great mechanical characteristics of our PFA-flex tubes offer a considerably longer life time in application areas, in which tubes are in a constant movement. This leads to an increased equipment safety, a reduction of maintenance requirements and, therefore, to a reduction of operating costs.

Properties

- Outstanding bending fatigue strength

- Higher life-time under dynamical and mechanical strain

- All other chemical and electrical properties are at the same outstanding level of standard PFA

Products

APT produces PFA-flex-tubing from a minimum inner diameter of 0,10mm to a maximum diameter of 110 mm or 0.004” to 4.000”.

Within this range we manufacture any desired dimension in natural transparent or coloured.

Samples of our PFA-flex-tubes in standard dimensions are available on request.

Depending on customer’s demands, PFA-flex-tubes can be packaged in defined ring lengths, coiled on spools or supplied in cut-off length.

Application areas

PFA-flex-tubes are being used in applications where the material is exposed to extreme movements and high mechanical stress. Typical applications are:

- Mechanical engineering

- Laboratory techniques and process engineering

- Painting technology

- Robotic applications